Innovation

Think Blue, Sail Different

FOR A DESIGN

Composite boats without moulds thanks to topological optimisation

Our ambition is to reduce the carbon footprint of our projects to a minimum through the use of advanced calculation techniques, while drawing on manufacturing methods that have proven their effectiveness for many years. By rethinking the way we design boats right from the design stage, we make the most of natural and recyclable materials while retaining the performance and design possibilities of the most modern boats.

Rethinking design for small series or one-offs is Ox Eye’s solution for the smallest possible carbon footprint.

Ecology, Performance, Design

Resistance and lightweight

Custom boats in small series or one-offs with a low carbon footprint and controlled weight thanks to new calculation and additive manufacturing technologies.

Topological optimisation makes it possible to use more eco-responsible materials and limit the boat’s carbon footprint, while retaining the light weight necessary for the boat’s speed performance.

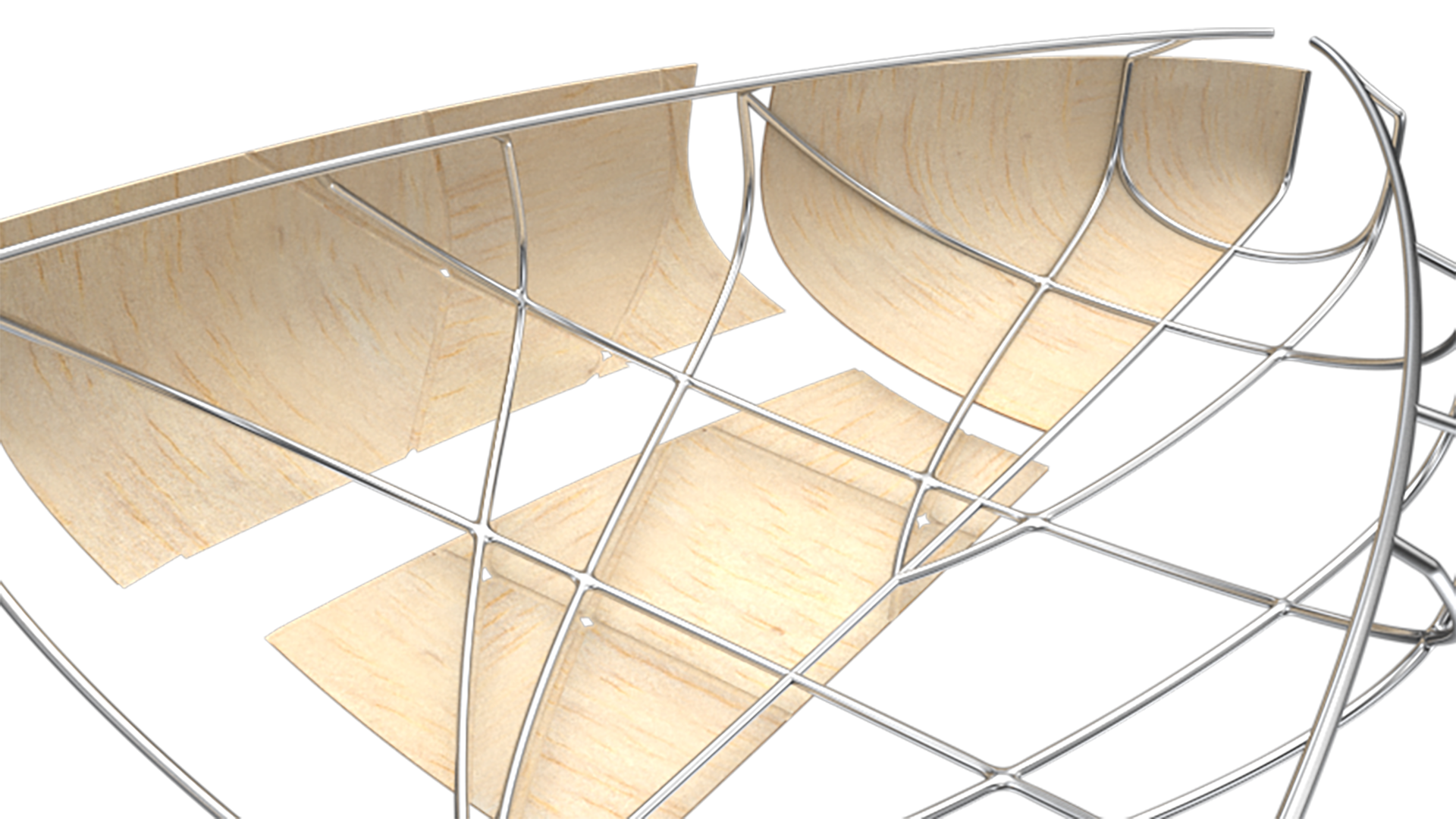

Here, topological optimisation is used for the structure of a float arm on an 8.8m trimaran.

Lightweight and design

Not only does the absence of moulds for the manufacture of boats significantly reduce the carbon footprint in the yachting industry by limiting waste (moulds made of non-recyclable composites, consumables used for infusion, etc.), it also allows for unique designs by eliminating demoulding constraints. This can be seen in the design of the FLAX 450, designed by Ox Eye in flax fibre with an optimised aluminium structure. This construction gives it a very light weight, an unbeatable carbon footprint and a modern, unique design.

Before the development of composite boats, all the manufacturing techniques were based on a structure, a skeleton on which the hull could be formed, in wood or with the natural materials available… Today, we want to use more natural techniques, but with the very latest in calculation and optimisation.